Manure waste management is the biggest challenge in broiler production. Reasonable poultry manure disposal methods and equipment are important for managing poultry manure. Membrane-covered fermentation, compost tank, traditional turnover-type fermentation, and biogas fermentation are mainstream technologies. Aiming at the chicken manure treatment needs of a broiler farm with 100,000 broilers**, we comprehensively compare and analyze the advantages and disadvantages of these four technologies.

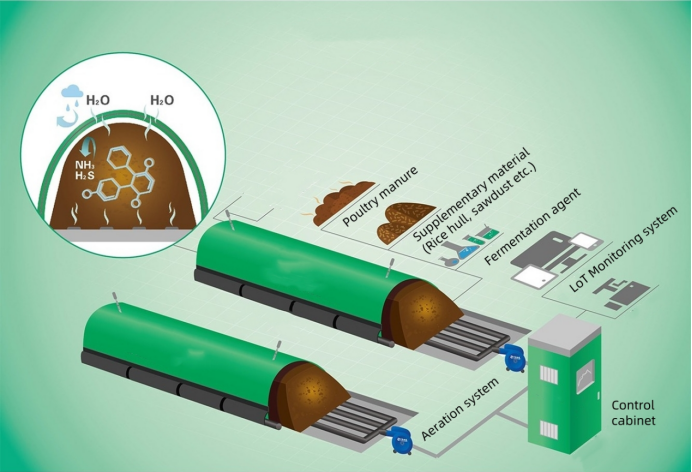

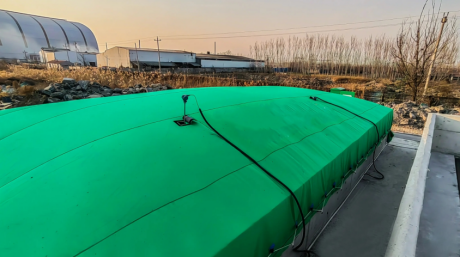

1. Membrane-covered fermentation (Nano film aerobic composting)

Principle: Use polymer nanofilm to cover the pile, promote aerobic fermentation through micro-positive pressure ventilation, and quickly decompose chicken manure into organic fertilizer.

Advantage:

- Efficient and fast: Fermentation cycle is 15-30 days, 50% faster than traditional composting.

- Environmentally friendly and odorless: The membrane material blocks harmful gases such as ammonia, and the nitrogen retention rate is over 70%.

- Strong adaptability: not affected by climate, operates outdoors, no factory required.

- Moderate investment: Equipment cost is about R$21,500 to $43,000 (100,000 birds scale).

Disadvantage:

- Membrane material needs to be replaced: lifespan 3~5 years, replacement cost $7,000~$11,500.

- Electricity support required: The aeration system relies on a stable power supply.

Applicable scenarios: Medium and large-scale farms that require fast, low-odor organic fertilizer production.

2. Fermentation tank (tank type/vertical high temperature fermentation)

Principle: Aerobic fermentation at high temperature (60~70℃) in a closed tank, and mechanized turning to accelerate composting.

Advantage:

- Stable fermentation: temperature can be controlled, and pathogens are completely killed.

- Occupy a small area: Suitable for farms with limited space.

- High automation: The turner reduces manual intervention.

Disadvantage:

- High investment: One set of equipment costs $71,500 to $143,000 (100,000 birds).

- High energy consumption: Daily operation power is around 18 kW. It runs 24 hours a day. So, daily electricity consumption is about 18 kW*24h = 432 kWh per day.

Applicable scenarios: Large-scale farms with sufficient funds and pursuing automated management.

3. Traditional turnover-type fermentation (windrow composting)

Principle: Open-air strip stacking, manual or mechanical turning to provide oxygen and fermentation.

Advantage:

- Lowest cost: Only a polishing machine ($14,300~$28,600 ) is required; no laminating or tank investment is required.

-Easy to operate: Suitable for small-scale farms or farms with poor economic conditions.

Disadvantage:

- Slow fermentation: cycle 30~60 days, greatly affected by weather.

- Odor pollution: Severe ammonia volatilization and high environmental risk.

- Large area: A larger composting site is required.

Applicable scenarios: areas with limited budgets and less stringent environmental protection requirements.

4. Biogas fermentation (anaerobic fermentation)

Principle: Chicken manure produces biogas (methane) in an anaerobic environment, and the biogas residue and liquid are used as organic fertilizer.

Advantage:

- Energy recovery: Biogas can be used to generate electricity or heat, reducing energy costs.

- Environmental protection and emission reduction: Reduce greenhouse gas emissions and comply with the carbon-neutral development direction.

Disadvantage:

- Highest investment: The Biogas project (including purification equipment) requires $143,000 to $286,000.

- Complex operation: The carbon-nitrogen ratio needs to be adjusted (chicken manure has high nitrogen content, so straw needs to be added), and low temperatures in winter affect gas production.

- Methane slurry is difficult to treat: high ammonia nitrogen content, direct return to the field may burn seedlings.

Applicable scenarios: Areas with high electricity demand and policy support for biogas subsidies.

Comprehensive comparison table of chicken manure treatment for 100,000 broiler chickens

|

Processing |

Investment cost |

Running costs |

Fermentation cycle(days) |

Environmental protection |

Applicability |

|

Membrane-covered fermentation |

$40,000~$80,000 |

Low (electricity cost + bacterial agent) |

15~30 |

High (low odor) |

Medium and large farms, fast organic fertilizer |

|

Fermentation tank |

$71,500~$143,000 |

High (electricity + maintenance) |

15~25 |

High (closed) |

Adequate funding and automation are needed |

|

Traditional turnover-type fermentation |

$14,300~$28,600 |

Minimum (manual) |

30~60 |

Low (strong odor) |

Limited budget, small scale |

|

Biogas fermentation |

$143,000~$286,000 |

Medium-high (maintenance + raw materials) |

20~40 days |

High (Energy) |

Policy support, energy demand |

Recommended Solution

1. Economical: Traditional turnover-type fermentation (low cost, but poor environmental protection).

2. Balanced type: Membrane-covered fermentation (moderate cost, environmentally friendly, and efficient).

3. High-end: Fermentation tank (automated, stable, but expensive).

4. Energy type: biogas fermentation (high long-term returns, but large initial investment).

Optimal combination suggestions:

- Membrane-covered fermentation and biogas project** (part of the chicken manure produces biogas, and the rest is film-covered and composted).

- In areas where government subsidies are provided, biogas will be given priority,

- In areas where the organic fertilizer market is mature, membrane-covered fermentation will be given priority.

If further optimization is needed, the technical route can be selected in combination with local policies (such as promoting the resource utilization of manure and sewage in the entire county).

Hot News

Hot News2025-04-22

2025-04-22

2025-04-21

2024-05-05

2024-03-15

2024-04-15